|

Gas Tank & Fuel Lines

While the tank is out getting

cleaned, I started the preliminary work on the gas lines. Basically I have to

run all new line from the tank to the carbs. Most of the line will be coming

from John in the form of Push Lock hose designed for high pressure fuel

situations. I didn't want to use steel line as there would be a lot of custom

bending and compression fittings involved like Rick did on Aaron's car. It looks

great but running high pressure hose works just as well and is a lot easier to

work with. The hose and fittings that John provides is rated at 250 PSI

and is what he uses when he does installations. The TBI conversion requires a

low pressure return line from the fuel pressure regulator, so I'll just be

re-using my existing steel fuel line for that......I mean it's all just sitting

there doing nothing at this point!

|

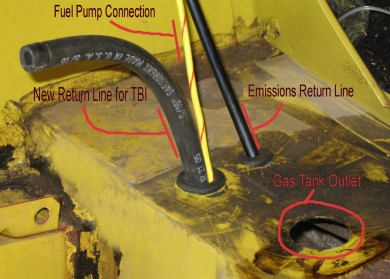

What a dirty looking

trunk....but no Rust :-) |

|

I've always had a slight gas smell in

my car but I could never find its source or even see any evidence of a leak.

When I pulled the tank there was a sponge-like donut that sat on the Gas Tank

Outlet hole in the picture above. The tank rested on it and the gas line passed

through it.....and it reeked of gas! My guess is there must have been a tiny,

infrequent leak at the compression fitting that worked its way to this donut

causing the smell. After a thorough soaking and cleaning, it now smells like

Purple Muscle now.

|

Source of Gas Smell |

|

Monday I'll drop off the fittings I need soldered

in to the gas tank and then it's wait for the tank to be done and John's kit to arrive.

December 1st and the

weather continues to be unseasonably warm with

temperatures in the high 50's to low 60's. I picked up

the gas tank today and for $50 it was acid dipped,

cleaned, tested and 2 fittings soldered in place.

Because the tank is steel and the fittings are brass,

the 2 "welding" options are: brazing and soldering.

Soldering was used because he believes it gives a better

seal in a liquid environment.

|

Tank Outlet

Fitting |

Fuel Return

Fitting |

|

|

For me,

one of the "challenges" is finding the right

fittings and sized to use in a liquid environment.

What made this a lot easier was Rick's knowledge of

what is the best fitting to use, coupled with his

ownership of a NAPA store or two. So basically Rick

gave me the part number and I went and bought it at

my local NAPA store.

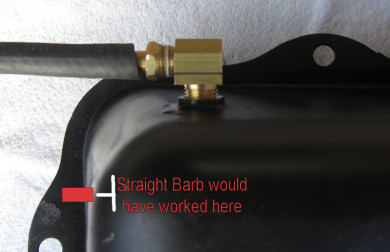

In

hindsight I would have located the tank return

fitting in one of two other locations. The spot I

choose requires an elbow or 90 degree fitting to

allow for hose clearance. I learned that from inside

the car there's lots of room above the tank but the

rear deck has a slight slope which limits clearance

on trunk side.......where I put the fitting.

|

I used a 90

degree elbow and a straight barb for the

return line |

|

|

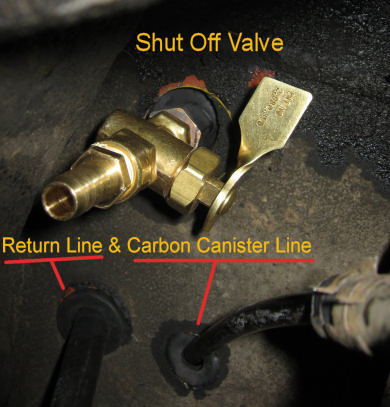

I took

Rick's expensive ($35) suggestion and sprung for the

NAPA fuel shut off valve. I know there are cheaper

alternatives but at this point.................. :-)

The fuel flow from the tank is gravity fed to the

pump so I just screwed the 1/4 NPT male fitting on

the shut off valve directly into the tank fitting. On the other side of the shut

off is a 1/4" NPT Male straight barb with a short

section of 3/8" hose that connects to the filter. It's a tight fit for the

fuel shut off valve relative to the frame and tank so I have

to remove its handle and reverse it to get enough clearance.

When it's in the open position, you want the "arrow"

end of the handle pointing at the tank. It was also

easier to screw this in with the tank leaning away

from it's vertically mounted position. I poured

about 1/2 gallon of gas into the tank and found no

leaks! Yippee............ and a quick turn of the

valve handle got the gas flowing...........on to the

garage floor! Damn hose jumped out of the container.

Well, at least the valve works, I wanted to mount

the filter in a horizontal postion directly before

the pump but space was at a premium so I moved it to

a vertical position right after the shut off valve.

|

Shut Off Valve

All Mounted |

Fuel Filter

Connected |

|

|

Next up

is the fuel pump......more

|