|

Differential Flange Machining

When you buy

your differential directly from

Goodparts, all the required "machine"

work has been done. But when you source one

on your own, there are certain things that

need to be done before it will all fit in

your car. I previously mentioned that the

tab on top of the differential needs to be

ground off. That's pretty easy to do as long

as you have an angle grinder. It's the other

"things" that really can't be done in the

home workshop. You may be tempted to tackle

the flange modifications on your own but a

look at the pictures below will probably

change you mind. If this work isn't done

perfectly, you might find

yourself with a pretty serious drive train

vibration.

The

first step in the Flange modifications

requires a metal lathe

|

Locked in chuck and aligned to

0.001" |

Cleaning face to remove surface

rust |

|

|

|

Cut

depth set to 0.0055" |

Final

face cut at exactly 0.0055" |

|

|

|

Boring bar cuts pilot access |

Recess is now complete |

|

|

|

Reducing diameter matches TR6

drive shaft |

Done:

Faced, Bored and Reduced |

|

|

OK.........so maybe you have a metal lathe

in your home work shop and can do the work

shown above but now you have to get the

holes drilled to perfectly match the drive

shaft flange. If you're even off by teeny

tiny bit, you've got problems.

So............do you have a.......

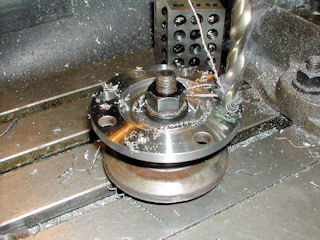

Bridgeport

Milling Machine?

|

Laser

aligned to index original holes |

Locating center of flange to

0.001" |

|

|

|

Readout set to center of flange |

Drilling Pilot holes |

|

|

|

Drilling new bolt holes |

Chamfering holes |

|

|

When you see

the old flange and then look at the finished

product, it probably doesn't seem like a

whole lot of work was needed. But when you

look at the step by step pictures you can

see that it requires some very special

equipment to do the job right.

|

Before |

After |

|

|

Many thanks to

my TBI friend Rick Patton who has a basement

workshop that most of us can only dream

about. If you want to see all the equipment

in his home, yes I said home, work shop

visit

his new web site. His shop is in the

"About Rick" section.

|