|

Running the Wires under

the Hood/Bonnet

Before running any wire you need a

couple of good tools: GB Crimping Pliers and British Wiring's Bullet Crimper.

This one's a bit pricey @ $45 but it gives you a perfect bullet crimp and

totally eliminates the need to solder the bullet connections. For that alone

it's worth the price. I am soldering all the other connections as I'm not

thrilled with the quality of the crimps that I'm getting with the GB tool. I'm

sure it's me and not the tool.

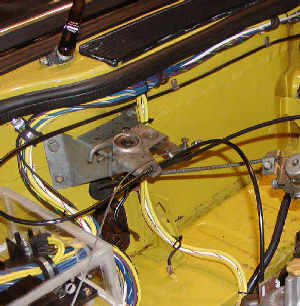

The first thing you do is lay out all

the wires according to how you want to route them under the hood (yes I know

it's really a bonnet) and always remember that old carpenter's adage "measure

twice, cut once". The left shot shows the wire run to the starter and the main

harness under the cowl while the right shows the solenoid connection.

Once everything is laid in place,

you can cut them to length and terminate them..... one at a time. I started on

the right side of the car and have completed the: starter solenoid, horn,

headlight, turn signal and side marker. Everything was going fine until I

pulled the carbon canister to gain access to the anti run-on valve and found one

of the wires to be hanging on by a thread.... and then it wasn't...

I don't even know if the valve works so I plan on

running the new wire to it and tie it off in case I have to replace the valve

after I finish the job.

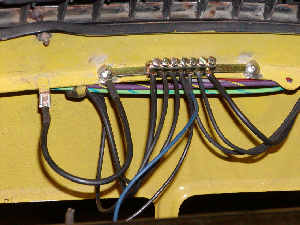

December 16th: Today I finished the front of the

car and have connections to the headlights, turn signals, side markers. horns.

alternator, coil and distributor. Dan supplies 12 ga wire for grounding the

headlights and 14 ga for all the other connections so I got a grounding block

and mounted it just below the grill.

I know I have a good solid ground

with this set up. What I don't know is how it'll stand up to vibration over

time. Maybe after I finish the job and test everything I'll use some Locktite on

the set screws.

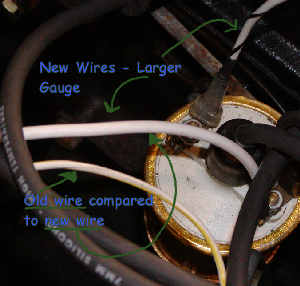

Pretty much every wire in this kit is

at least 1 gauge larger from standard. Below is a comparison of the 12 ga wire now

run to the coil versus the old 14 or 16 ga that was standard. Even the coil to

distributor wire (white/black) is a size or 2 larger.

The only problem I've run into so far

has to do with the electric fan. Because of the relay type used by Hayden for

their fan, Dan is trying to figure out an alternative way to wire it from his

power panel and using the recommended double throw switch. No big deal as all of

the wires have been run and tied off. So here's the wires from under the hood

that now have to go back into the interior. I need to get a new firewall rubber

grommet as the old one is pretty beat up.

Next

Up... the interior wiring

|