|

Trailing Arm Bushing Installation

I've got multiple things going on

that led to my decision to replace the old Trailing Arm bushings

with Goodparts' Nylatron bushings. First, my rubber bushings are

10 years old. Second, I'm installing his Trailing Arm Kit and

Third, I'm doing his Nissan differential upgrade.

I previously showed you

how to remove the old bushings

and installation of the Nylatron is quite easy IF you follow his

directions. DO NOT just pound the new ones in place and expect

them to fit. Unlike the front suspension, the trailing arms are

aluminum and subject to deformity and variances in hole diameter

and arm width.

But first let's take the time to

clean up those old dirty trailing arms. I hit mine with an

assortment of wire brushes on my grinding wheel and drill. Not

as good as having them bead blasted but they're good enough for

me.

|

Not too shabby for a few

hours work |

|

|

Once you get them cleaned up on

the outside, you need to clean out and true up the bushing

holes. This is best accomplished with a Dremel flap sanding

wheel and brake cylinder honing tool. The flap wheel is far more

aggressive and the honing wheel really smooth's things out. The

"tool" on the right consist of a 6-1/4" bolt, a 3" piece of

1-3/4" PVC pipe, an old differential mount washer and a 15/16"

socket. More on that later.

| The

Obvious Tools |

and then

there's this Tool |

|

|

If you read the Goodparts'

directions you'll see that you have to test fit each individual

bushing BEFORE installing both bushings. The idea here is to

true up the hole, install one bushing, test that the stainless

sleeve slides easily in and out, remove the bushing and repeat

on the other side. There's 4 bushings per arm so you'll do this

4 times per arm. DO NOT install both bushings at once until

after you've tested the fit of the stainless sleeve. The problem

is that you can pound in a bushing but the sleeve hole will be

slightly deformed binding up the sleeve. You HAVE TO WORK one

bushing at a time. The bushings themselves ARE NOT a finger

tight fit. I used a 28 oz dead blow hammer to get them to the

point in the picture below and then snugged them up with the

"tool" in the picture above.

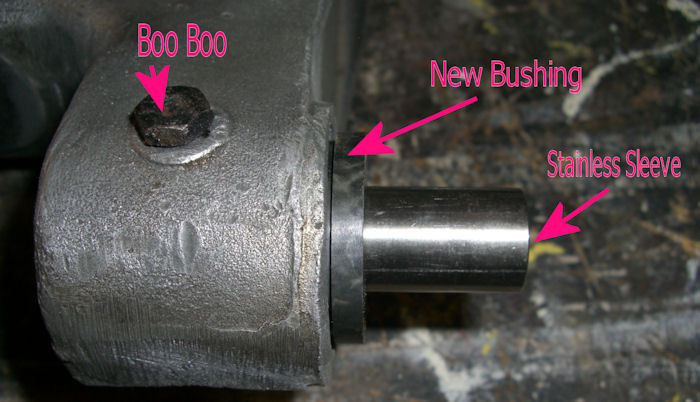

|

That Sleeve should slide

back and forth with slight finger pressure. More on

the Boo Boo later |

|

|

Here's how those

tool components go together to pull the bushing back out.

Now test fit the other bushing for this side. Once

they both fit correctly you can install both on one

side on one arm. |

|

|

This is how I used the

"tool" to snug each bushing in to place.

The socket pulls it tight to the arm.

It will be obvious when it "bottoms" out |

|

|

Once you get all 8 bushings in

place you need to determine which size washers to use to obtain

the proper clearance within the bracket. The kit includes 15

washers....... 5 sets of 3 different sizes. Grab a bolt and a

feeler gauge to get the right combination.

| 15 washers with recess from .010

- .050" |

They'll sit on sleeve like this |

|

|

IMPORTANT: Here's the step that people don't

understand or forget to do. You DO NOT determine the

washers to use by putting the assembly in the bracket. The

bracket is deliberately set wide to make installation easier.

When you torque the Pivot Bolt to the proper setting it will

snug the bracket up against the washers. So how do you determine

the proper washer thickness to use? Very easy.....Just slide a

bolt though the whole assembly with assorted sized bushing on

both sides, tighten and measure. Keep trying different

combinations until you find one that works.

Oh yes......the Boo Boo...........

Goodparts recommends the installation of grease fittings on the

trailing arms. Even thought Nylatron is self-lubricating, it

doesn't hurt to hit it with a shot of grease now and then. The

directions say to "install a fitting straight down......." which

I interpreted to mean install a straight fitting as opposed to a

45 or 90 degree fitting. What he really meant was to install a

straight fitting pointing down.............as in a fitting on

the BOTTOM of the arm. DUH...........my first set of holes were

drilled into the top of the arm and, trust me, that won't

work.....won't even come close to working. Hence the plugs on

the top of the arm.

| Wrong

Way |

Right

Way |

|

|

Time to move on to the

adjustable kit.

|