| Everything back

on........... I won't go through the steps to set

the bearing "pressure" as it's different with

Uncle Jack's Stub Axles from stock. |

|

| And after I got the

hub back on I looked over and saw the F@$*#ing

shield on the floor! And the only way you can get

this back on is to totally remove the hub assembly

again........ARGHHHHH...... and to add insult to

injury..............there's no need to even remove

the darn thing. Live and learn............... |

|

|

The

kit comes with a bag of bolts and two new brake

lines. |

|

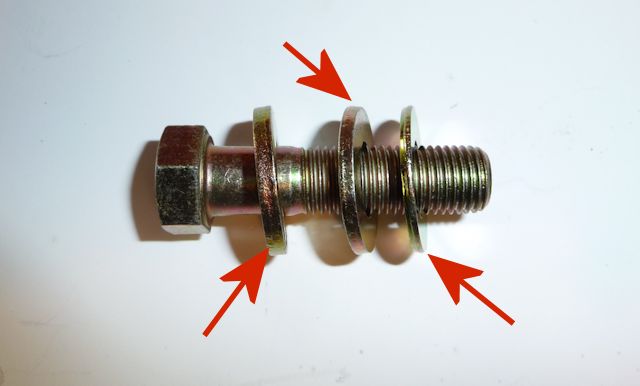

| The kit comes with

new caliper bolts and four sets of three different

thickness 7/16" washers. These are used to set the

spacing of the caliper around the rotor. |

|

|

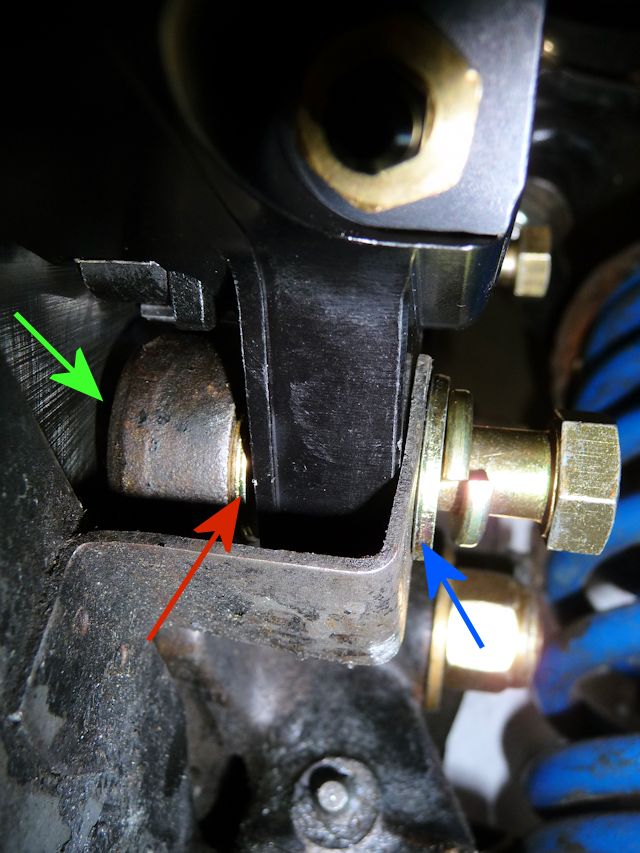

IMPORTANT:

There's two things you need to determine: what

size washer is needed at the red arrow to center

the pads on the rotor AND what size washer is

needed at the blue arrow to keep the bolt from

protruding through the mounting hole, green arrow,

and hitting the rotor. I used the thickest washer

at the blue arrow and the middle size as the

spacer, red arrow. |

|

|

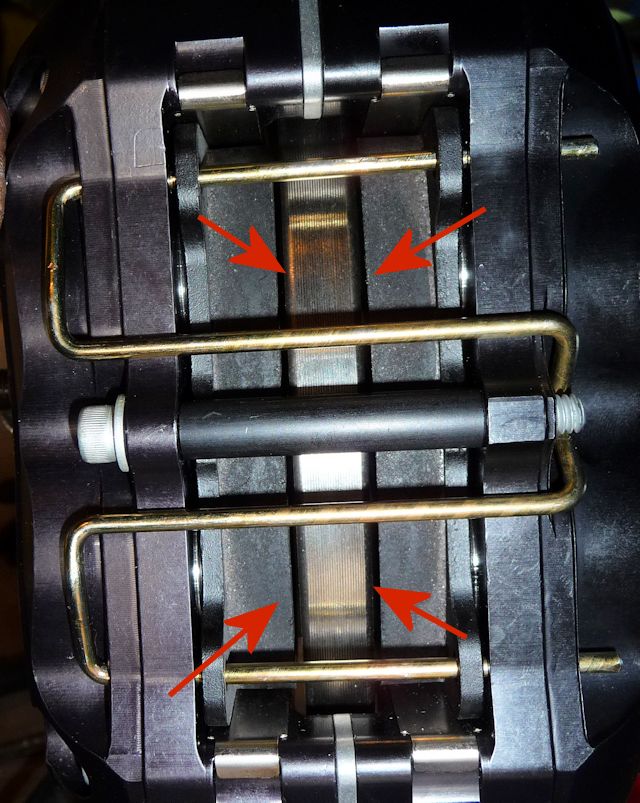

As

you can see the rotor is centered between the

pads. |

|

|

This

label covers the brake fluid inlet hole for the

fitting. |

|

|

Just

an empty hole for now............... |

|

| Here are the brake

line fittings.............. see how they have

those little plastic caps on them? |

|

| This is the fitting

that goes into the back of the caliper. Don't do

what I did and remove ONE of the plastic covers

and then use sealing compound on .... the wrong

side! The compound goes on the flat

end..........so I had to clean all the compound

off of the other threads. |

|

|

Per

the instructions, I used a Teflon thread sealer. |

|

| This was the only

scary part for me. The fitting screws into the

caliper and has to end up facing forward and at a

45 degree angle up. Seeing as the caliper body is

some sort of lightweight alloy, I had visions of

stripping the threads. |

|

|

But

it all went around just fine and then threaded on

the brake line. |

|

| This fitting goes

on the frame and the red arrow end points up and

the green arrow end secures it to the frame. |

|

| The directions said

to secure it tightly to the frame but if you do

that, it's almost impossible to get the steel line

flared fitting lined up properly. The paper towel

covers the fitting to keep anything from falling

into the line. If you keep this fitting loose, you

can angle it to line up with the flared fitting,

attach the flare and tighten it to the frame

fitting. Once that's tight, you can secure the

frame fitting to the frame. |

|

|

Here's everything all connected and tight. |

|

|

Looking good........... just need to bleed them. |

|

| For bleeding the

brakes, I use this old master cylinder cap with a

regular old tire valve stem. |

|

| When you buy the

valve stem the package tells you what size hole

its made for.........so drill a hole that size in

the cap and pull the valve stem through. You don't

need much pressure +-10 psi is plenty and doing it

this way eliminates the need for someone to work

the brake pedal. |

|