|

I even used an

old pair of gloves as I didn't want to wreck

my new ones with

embedded pieces of aluminum. Now would you really want to work bare

handed? |

|

Two

words: Measure & Tap Oil......OK, that's more then

two words but make sure you get a high quality tap

oil made for aluminum and measure twice and drill

once.

|

This is what Rick

recommended I use, but I wish I got it in an

aerosol can to spray

in the holes. It's a little messy shooting it in with a can |

|

|

I used my caliper

to measure the depth of the existing hole.

The KeenSerts require

a minimum depth of 1/2". |

|

|

Then transfer the

depth to your drill bit and tape it off |

|

As noted

previously, Rick has machined this jig to very tight

tolerances and I had a little trouble getting my "X"

drill to fit in the alignment insert. I figured that

the drill bit probably had a burr or two on it so I

just grabbed the insert and worked the drill

in...........make sure you're wearing gloves as the

insert will try to twist if the drill binds. Don't

forget the Tap Magic oil for the drilling and

tapping! After you drill the three holes, clean out

all of the chips before tapping. I used a vacuum and

compressed air.......but don't blow any chips into

your eyes!

|

Make sure you

have a good grip on the insertion jig in

case the drill binds |

|

|

Tapping is easy

when the alignment is perfect. |

|

|

But these are my

nice new threads.... and there is plenty of

TA "meat" to drill & tap. |

|

All that's left now is

to install the KeenSerts, lock them down and thread

in the studs.

|

Thread them in by

hand. No tools required....yet |

|

|

I used a 5/16"

wrench to get them nice and flush with the

TA surface. Don't overdo it! |

|

|

Thread them in

until you hit the locking tabs.

The threads should be pretty flush with the

TA face. |

|

|

KeenSert Tool

that smacks the locking tabs in place.

A few good hammer whacks does it. You'll

hear it when it's flush. |

|

|

Tabs all locked

down |

|

Now that

you've done three of them, thread in the studs you

removed before, and back out the three studs that

still need to be done. I kept the studs somewhat

loose but I don't think it really mattered as

there's no free play in the KeenSerts.

When

you're all done, here's what it will look like!

|

Six studs that

will not strip! |

|

|

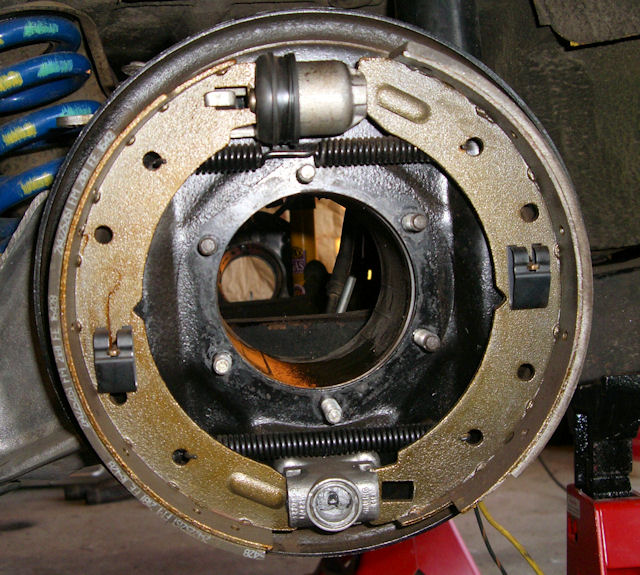

And here's the

brake back on the TA. A perfect fit. |

|

|

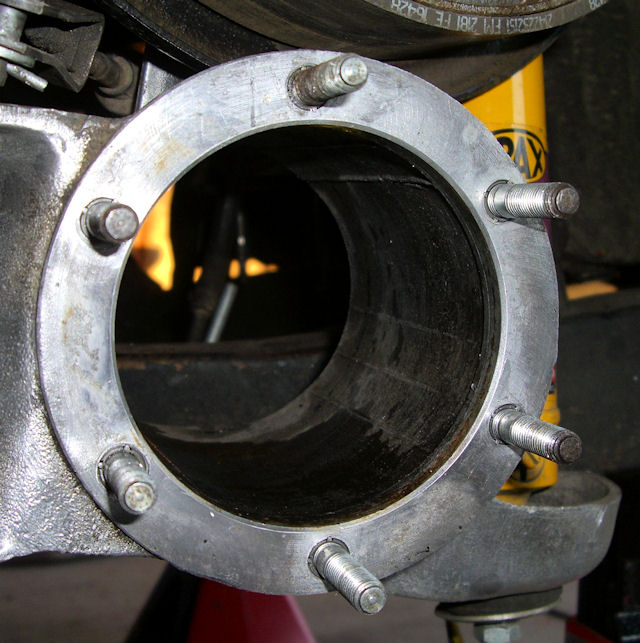

And a test fit of

the new upgraded CVJ hubs |

|

|

These things are

beefy :-) |

|

Next Up

is my very unscientific

strip test of Keen-serts.