|

Trailing

Arm Jig - The Kit Contents

The six studs that hold the hub and brake plate to

the Trailing Arm (TA) are prone to stripping even when staying at the

recommended 16 lbs of torque. The problem lies with the fact that the TA is cast

from aluminum. One solution is to drill out the 5/16" stud hole and tap it to

3/8" but you're still dealing with a steel stud being anchored in aluminum. The

better solution is to use a locking threaded insert like KeenSerts which are

easily ordered at WWW.McMaster.com part#

92070A250. The challenge, however is in drilling the old holes out the required

insert size while maintaining the drill and tap exactly perpendicular to the TA

face. Even the studs as installed at the factory have some misalignment in them

which required the holes in the axle hubs and brake back plates to be slightly

oversized.

I had a few people on the various Mail Lists and

Forums suggest the use of a jig to maintain alignment but no one has ever made a

precision jig that could make this virtually "foolproof". And that is where I come

in......the fool. Basically I drew up a design that had the jig anchored to 3 of

the 6 studs while drilling and tapping one of the studs. Then you'd move the

whole assembly to 3 more studs so you can drill one more hole. I shared the idea

with Rick Patton, of TBI

and Fan Eliminator Fame, who immediately offered a far simpler and more

elegant solution. His jig goes over all 6 stud holes and is secured to 3 of the

studs while you drill and tap the other 3 studs. Then you rotate it just once

and do the 3 remaining studs. He's tested it on a spare TA that he has and it

worked great so I'll be doing mine after the New Year. Please note that

this is for use with KeenSerts which require an "X" drill size and 7/16-14

bottoming tap. There's some confusion here because a

7/16-14 tap is supposed to use a "U" drill size BUT.................the

KeenSerts instructions specify the larger "X" drill size. So don't make the

mistake of using a "U" drill. The KeenSerts directions also call for a

countersink but you won't need one when you use this set-up. If you were

"free-handing" the tap, the countersink helps to line you up and get you

started. The tap insert used here does all of that for you.

This ended up working so

well that Rick now

has them for sale on his site.

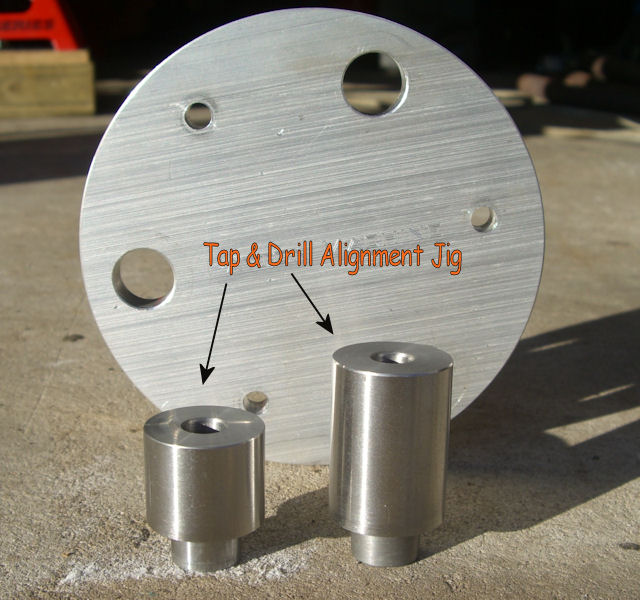

A round aluminum plate

with hardened steel inserts:

One for the drill and one for the tap....... the drill one weighs

over 1/2 pound! |

|

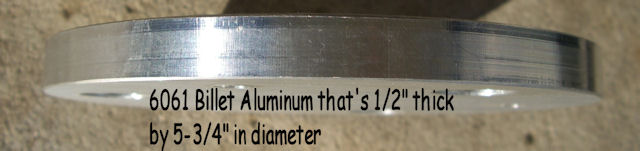

| Yup......1/2" Thick |

|

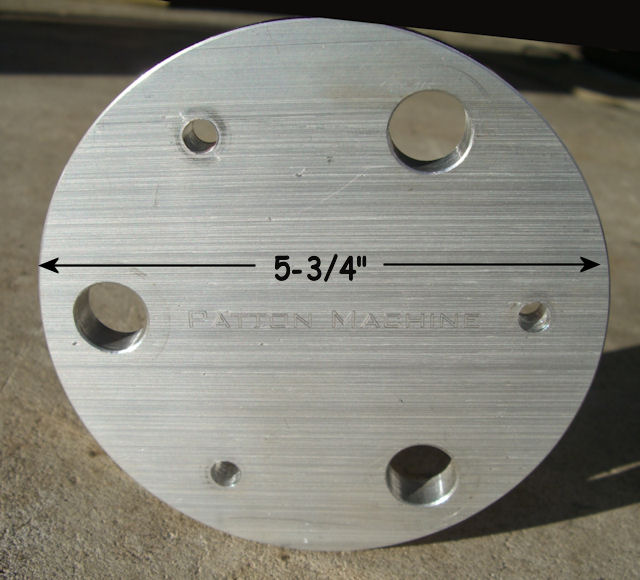

| Says it all! |

|

The bottoming tap and

"X" drill bit are not included with the jig.

Bottoming Taps and "X" Drills aren't your normal tools so make sure

you get the

right things.........and yes......"X" is really a drill size. |

|

| Here's how they slide

together - machined to very precise tolerances |

|

Time to test fit and

prep the work area.

|